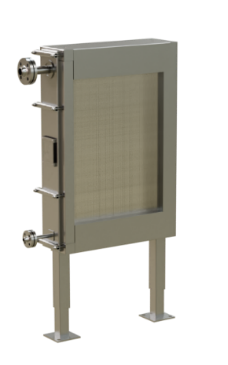

Steam Air Heaters / Steam Heat Exchangers / Steam Coils Air Heating

Main Features

- Finned tube heat exchanger type using steam to heat up gaseous media (e.g. air), also called steam air heaters, steam heat exchangers or steam coil air heaters

- Customized according to client specification and request (e.g. equippable with air pre-heater recuperator or with optional electrical or oil heater to reach higher temperatures)

- Insulated housing (fully welded, sanitary design) and extractable elements

- Condensate cooling and innovative safety system (see below)

Selected Project References

Click on the images to enlarge.

Materials And Characteristic Values

- Housing: Stainless steel (AISI 304 or AISI 316) with mineral wool insulation

- Finned tubes: Stainless steel (AISI 304 or AISI 316)

- Fins: Aluminum or stainless steel

- Air volume: up to 150’000 kg/h per device

- Discharge temperature: 80 to over 200 °C, depending on steam pressure, or more than 300°C with optional electrical or oil heater

- Steam pressure: up to 70 bar

Condensate Cooling

- Use of flash steam and condensate of the steam coils to pre-heat the process air

- Separate flash steam and separate condensate stage, for stable running conditions at different capacities

- Returning of water without any flash steam to the tank

Safety System

- Innovative and field-proven system consisting of pressure sensors, valves and bypass piping

- To avoid steam hammers which caused a quite long history of damage at steam heat exchanger units without safety system

- Steam hammers occur when the heater coils fill up with water especially during low capacity cases

Get impressions about our high quality products by viewing the photographs shown in the home section of our website.