#HIRING!

Anytherm is growing – do you want to grow with us? Exciting job offers available!

Please find our current job opportunities in the Career section.

What we do

Anytherm advises its customers in a solution-oriented, competent and neutral manner and calculates, designs and produces custom-made systems for heat exchange and heat recovery. Our units are used worldwide: e.g. in air handling for the process industry as well as for the recovery of the thermal energy contained in the process exhaust air. Advising our customers on heat recovery and energy saving potentials completes our versatile field of activity.

Anytherm’s main products are custom-made heat exchange and heat recovery units for industrial applications. We deliver turn-key systems with insulated casings which can be combined with CIP systems, armatures, filters, fans, sorption wheels, etc. For cleaning and maintenance, the heat exchanger elements can be easily pulled out of the casing, without removing the insulation. For heat recovery systems, our heat exchanger solutions can be executed with integrated CIP systems, with larger fin pitch, in pillow-plate / thermo plate or bare tube execution – especially feasible for handling dust or particle loaded applications.

Anytherm’s services cover the whole process within the scope of heat exchange, heat recovery and energy efficiency improvement projects. Learn more about our products, applications and consulting services by clicking the links below.

See the photographs shown below and get impressions about our high quality products.

How we work

Anytherm achieves team- and service-oriented long-term collaborations with our customers, with our suppliers and within our company by being curious, solution oriented, honest and kind.

Anytherm strives for providing solution orientated and impactful energy consulting services and the worlds most cost-efficient high-quality products in its field of custom-made solutions for industrial applications by working cost-effective, quality driven, passionate and smart.

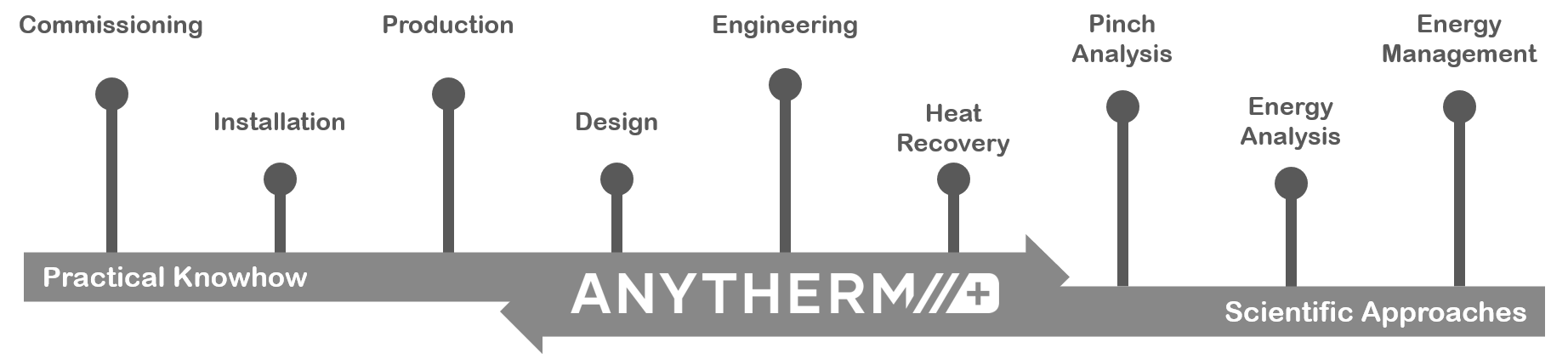

Anytherm differentiates with its custom-made turn-key solutions and consulting services by combining practical knowhow with scientifical methods.

Anytherm contributes with its products and energy consulting services to an improved economical and ecological sustainability by lowering investment, maintenance, energy cost and emissions.

Any questions about heat exchanger applications or regarding heat recovery and energy efficiency potentials? Don’t hesitate to contact us – we would be glad providing you with our services and our custom-made solutions!

Good to know

Practical and profound knowhow in process industry applications combined with

Scientifically based methodologies in energy efficiency analysis and energy management

Resulting in optimal heat exchange, air handling and significant heat recovery, efficiency improvement and CO2-reduction achievements

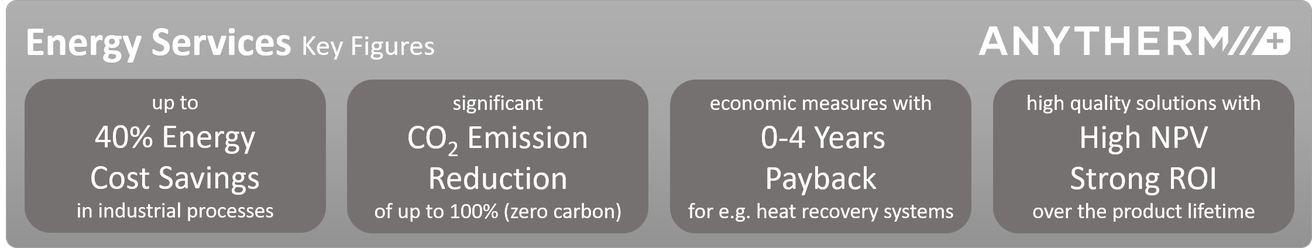

Energy Consulting Key Figures

Product specifications

- All products and services are customized according to client specification and request

- Insulated housings (mineral wool insulation material), fully welded, sanitary design

- Extractable elements (for cleaning and maintenance) without removing the insulation

- High quality products (welding quality assurance system EN ISO 3834-2, plant production control EN 1090) and materials (stainless steel AISI 304 or AISI 316)

- Profound and reliable knowledge in heat exchangers e.g. for spray drying process air treatment and heat recovery applications

- Swiss engineering service (professional, timely and customer-oriented)

Product References

A small selection of references from Anytherm projects of the last two years:

More information on our versatile, worldwide projects and its impressive process air handling, heat transfer, dehumidification and heat recovery units can be found in the References section.

Impressions

Get impressions of our high quality products with pictures from everyday production life.

Heat Exchangers, Heat Recovery and Energy Efficiency – Because Any Therm Matters