Industrial Heat Recovery Systems

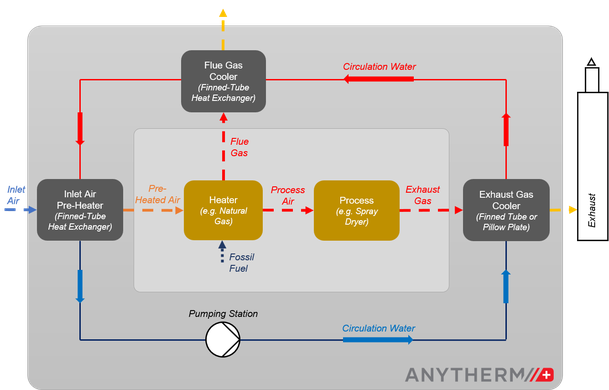

Heat recovery circulation systems (heat recuperation and heat release at different places on your site) and

direct recuperation systems (heat recovery and release within the same unit) can be provided.

If you first need to know the overall and most economical heat recovery and CO2-reduction potential of your site? Then our energy consulting (e.g. the Pinch analysis methodology) is the right service to choose:

Main Features

- System to recover heat from exhaust air and flue gas (from combustion processes - if available) to preheat inlet air to be heated up for process applications (e.g. spray dryer)

- Significant energy and net savings due to short payback times (often below 2 or even 1 year) combined with the long product lifetime of often more than 30 years

- Significant CO₂-reduction for your company

- In many countries or regions it is possible to get subsidies (public financial support) for heat recovery systems as they contribute to less emissions. Don't hesitate to contact us if you want to know more about this possibility.

Heat Exchanger usage

- Use of the very cost efficient finned-tube heat exchanger units as inlet air pre-heater and flue gas cooler

- Use of finned-tube, bare-tube or pillow-plate heat exchangers (i.e. with included CIP system) for heavily dust loaded exhaust air applications

- Multiple heat sources (e.g. additional steam heating or hot water units) as well as heat sinks can be connected to the water circuit

- The entire system including pumping station as well as piping and instrumentation can be offered – all out of one hand

Economic analysis / Subsidies

On demand, we can also offer you economic analysis (Payback, NPV, IRR) for heat recovery systems (which often pay back within 1-2 years) and support you regarding potential subsidies (public financial support - as heat recovery systems contribute to less emissions).

Cost-Efficient and Easy to Clean / Low Maintenance Heat Recovery Systems