News

Don't miss any news from us by following us on LinkedIn.

Megawatts of heat recovery for nestlÉ!

A LONG-STANDING AND CLOSE PARTNERSHIP WITH NESTLÉ ON HEAT RECOVERY OPTIMIZATION SHOWING IMPRESSIVE RESULTS IN ENERGY SAVINGS AND CO2 REDUCTIONS!

Anytherm delivered its third consecutive large exhaust air heat recuperator to Nestlé, marking another milestone in our ongoing partnership. The latest unit, identical to the one previously delivered to a Nestlé spray drying facility, was installed last week, while an even larger unit was successfully supplied to another Nestlé site a few months ago.

The three heat recuperators each feature significant heat recovery capacities of 1.3 and up to 2 Megawatts. With annual energy savings of up to over 20'000 MWh in total, these systems reduce CO2 emissions by approximately 5'000 tons per year – equivalent to the emissions of about 2'000 cars or the energy consumption of about 2'100 households per year.

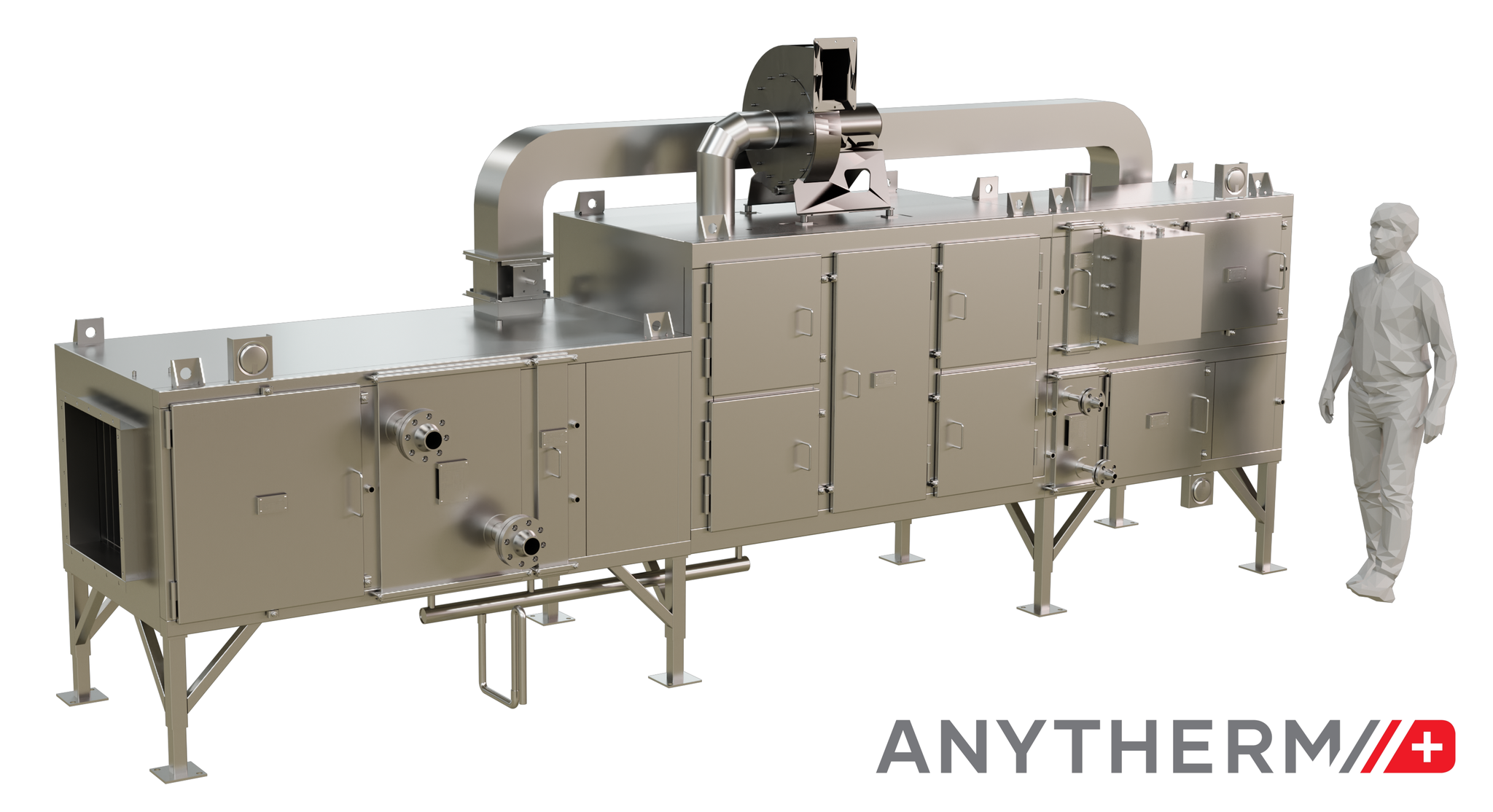

With imposing dimensions of about 10x3x4 meters and a weight of 13 to 17 tons per unit, the installation process of the heat recuperators involved inserting the housing by crane through the roof – a spectacular procedure, the safety of which was previously calculated by Anytherm using FEM analysis and then tested in reality at Anytherm's production site by performing a dynamic load test.

Our expertise in heat recovery process technology has enabled us to develop heat recovery system that combine maximum durability with optimized performance and efficiency. The heat recuperators are designed to maximize the efficiency of heat recovery by going into condensation, achieving increased energy savings.

The heat recuperators consist of heat exchanger elements connected in series to maximize heat recovery, thermally insulated inlet cones to minimize energy losses, and specially designed outlet cones for effective condensate drainage. The heat recuperators are equipped with sight glasses for visual inspection and a CIP (Cleaning in Place) system to remove powder accumulations from the heat transfer surfaces. In collaboration with Nestlé, Anytherm conducts CIP studies to further optimize the cleaning process.

These heat recovery solutions result from our close cooperation with Nestlé, focusing on the optimal integration of heat recovery systems, leveraging Anytherm's expertise in pinch analysis methodology, technical feasibility, cleanability, and optimal integration into spray drying processes. This joint initiative represents a significant contribution to enhanced sustainability in spray drying processes worldwide. We thank Nestlé for their trust and the excellent collaboration!

87'000 kg of weight, 338'000 kg/h of production air!

DELIVERY OF 3 BIG AIR INTAKE, FAN AND STEAM AND ELECTRICAL MAIN AIR HEATER UNITS; SUCCESSFUL COMMISSIONING OF THE FIRST AIR INTAKE-FAN-MAIN AIR HEATER COMBO IN NORWAY

During the last weeks, Anytherm delivered a large project consisting of three big air intake units and three big main air heater units to a customer in Norway, producing biopolymers, speciality cellulose, biovanillin, cellulose fibrils and bioethanol within its biorefinery. Two weeks ago, the first air intake and main air heater units of the project were successfully comissioned and are running smoothly.

The project specs are impressive: Unit weights of 20'000, 27'000 and 40'000 kg and air massflows of 76'000, 102'000 and 160'000 kg/h, filtering and heating production air from -20°C to +260°C at steam pressures of approx. 30 barg.

The air intake units consist of winter coils, G4 and F7 filter stages and noise absorbers followed by large fans. The main air heater units consist of water preheaters, steam, flash steam, and condensate stages as well as large electrical heaters including complete thyristor control units. Furthermore, Anytherm was responsible for engineering services such as FE analysis for snow and wind loads, transport to the customer, installation and commissioning supervision, and more - providing our customer with an optimal service in close cooperation during this very exciting project.

Production of two large DesiCcant Wheel Air Intake Dehumidifer Units and A Large Heat Recuperator

Impressions taken during the production of two large air intake desiccant wheel dehumidifiers and a large heat recovery system with integrated CIP system for food processing facilities in Germany and the Netherlands.

The air intake units, which process and dehumidify 200'000 kg/h of production air, are quite impressive: a total weight of 65'000 kilograms and dimensions of around 12x5x7 meters (LxWxH) each.

The heat recovery system, with imposing figures of 17'000 kg and 3x4x8 meters, achieves annual energy savings of around 13'000 MWh. It reduces emissions by more than 2'500 tons of CO2 per year: the equivalent of the annual emissions of over 1'000 households!

09. January 2024

Season’s greetings from Anytherm

It is with great gratitude that we look back on a busy and successful year - being very grateful for the large number of projects we were able to carry out. We would like to take this opportunity to thank our customers, our partners and, last but not least, the entire Anytherm crew for their trust and the successful and pleasant cooperation during the year. We are thankful that we were able to make a sustainable contribution in the areas of heat transfer, process air treatment, heat recovery and energy consulting.

Merry Christmas and a successful, peaceful, healthy and happy New Year!

24. December 2023

"heat recovery is essential. There is no way around it." Anytherm presents at the Energy Agency of the Swiss Private Sector (EnAW) Symposium 2023

Speaking to 350 company representatives from among the largest swiss companies and energy consumers in the commercial sector, our head of energy consulting, Tobias Helbling, presented the significance and benefits of Anytherm's heat recovery analyses and solutions for industrial applications:

Thermal energy savings of up to 40% in energy-intensive industrial processes combined with short paybacks of 2-4 years are not only totally worthwhile from an economic point of view, they also make an essential contribution to achieving energy and climate targets of our customers.

sorption dehumidifier for lithium battery production in usa

Anytherm has been revarded to providing two sorption (desiccant wheel) dehumidifier units to be applied in a lithium battery production of a leading electric car manufacturer.

Beside the main applications of our heat exchange and heat recovery solutions within the food and dairy as well as chemical and pharma industry, lithium battery processing applications are gaining of importance. Anytherm recently also produced a large heat recovery system for a European battery production facility, significantly lowering operation/energy cost and CO2 emissions.

More information about our products applied in lithium battery processing can be found in our Applications / Battery Processing section.

More space for our growing team - new location

We moved into our new premises at the beginning of the year, creating space for our growing team. With the perfect mix of spacious workplaces equipped with state-of-the-art technology, open exchange and separate meeting and conference rooms, our new office offers the optimal space for intensive, concentrated as well as communicative work. We look forward to meeting you in Switzerland or at our next conference call.

Our new business location address is:

ANYTHERM AG, Laubisruetistrasse 72, 8713 Uerikon, Switzerland

Season’s greetings from Anytherm

We look back with great gratitude to a very busy but successful year – unfortunately, also a challenging year with geopolitical conflicts or the threat of energy shortages. We are very grateful for the large number of projects which we have been able to carry out. We are constantly expanding our highly engaged Anytherm Team to serve all of our valued customers. It fills us with pride that we have been able to make sustainable contributions: in the area of heat transfer, process air treatment and last but not least with our impactful heat recovery systems and energy consulting services. Merry Christmas and a successful, peaceful, healthy and happy New Year!

24. December 2022

Processing and heat recovery of 5 million kilograms OF PROCESS AIR per hour

Our updated project reference list is available. Don't hesitate to contact us if you want to learn more about our numerous and versatile projects.

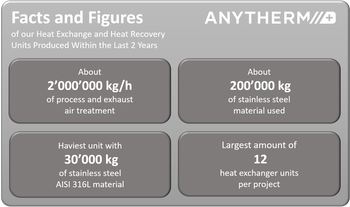

Providing solution oriented consulting services and maintenance friendly high quality solutions at internationally competitive prices, our units and services are being used all over the world. Within the last years, we delivered heat exchange and heat recovery units made of over 500 tons of stainless steel material - processing and/or recovering more than 5 million kilograms per hour of production and exhaust air. We would like to express our gratitude to our customers all over the world for the trust placed in us.

Christmas and NEw Year campaign 2021

At Christmas and New Year, people enjoy being together and also like to exchange gifts. Also this year, we wanted to take this beautiful tradition as an opportunity to think of those who have less - who may even be in urgent need of a gift.

Instead of sending greeting cards and customer gifts, we therefore once again supported the aid organization Himalayan Life with a donation. With our contribution of CHF 5000, the organization can provide urgently needed help, especially in the challenging times during the Covid pandemic. This year the help was also very important, as the village of Yangri was hit by a flash flood. With the help of the donations, they can now slowly rebuild the school and the houses of the locals. More infomation about Himalayn Life and its important and purposeful projects can be found on himalayanlife.com.

Season’s greetings from the entire Anytherm Team

With great gratitude we look back to a busy, challenging but successful year.

We would like to take this opportunity to thank you for the excellent collaborations and the exciting projects we have carried out together.

Merry Christmas and a successful, healthy and happy New Year!

24. December 2021

commissioning of Main Steam Air Heater for lArgest milk powder Spray Dryer in europe

Last month, two of Anytherm's engineers supervised the commissioning of the main steam air heater supplying process air to the largest milk powder spray dryer in Europe.

The steam air heater is designed for an airflow of over 200'000 kg/h, maximum operating air outlet temperature setpoint of 215°C and maximum allowable steam pressure of 27 barg. It consists of 2 units welded back-to-back on site. The complete steam air heater unit includes 1 filter section as well as 5 heater sections (water, flash steam/condensate and 3 steam sections).

Anytherms commissioning service supports the safe and secure implementation as well as operation of heat exchange and heat recovery systems after installation. Especially for bigger steam air heater and sorption dehumidifier units, our commissioning supervision is highly recommended.

12. November 2021

500 tons of stainless steel Processing over 4 million kilograms OF PROCESS AIR per hour

Our updated project reference list is available. Don't hesitate to contact us if you want to learn more about our numerous and versatile projects.

Providing maintenance friendly high quality solutions at internationally competitive prices, our units and services are being used all over the world. Within the last years, we delivered heat exchange and heat recovery units made of nearly 500 tons of stainless steel material - processing and/or recovering more than 4 million kilograms per hour of production and exhaust air. We would like to express our gratitude to our customers all over the world for the trust placed in us.

Finalization of former Brunner Thermo projects

A very busy period around the turn of the year lies behind us, in which we were able to complete numerous projects.

Despite a generally high workload, Anytherm stood by its customers and bought out all the running projects of its former (bankrupt) competitor Brunner Thermo and finalized them on behalf of its customers.

Furthermore, Anytherm employed the majority of the former Brunner Thermo engineering team and can therefor e.g. assist you in providing replacement heat exchanger units formerly supplied from the concursive Brunner Thermo.

Merry Christmas And happy new Year

A challenging but successful year for Anytherm with many exciting projects is coming to an end. We would like to take this opportunity to thank you for your trust and the successful and pleasant cooperation during the year.

We wish you a Merry Christmas, a successful and Happy New Year and are looking forward to a continued good cooperation.

24. December 2020

Ready for your pending project

Anytherm is at your disposal with full effort in assisting, finalizing and realizing your pending projects placed or intendet to place at our former competitor Brunner Thermo GmbH which had to declare bankruptcy.

We are pleased to inform that we have employed Maciek Szczech and Tomasz Westrych - the two most experienced engineers of former Brunner Thermo - and can therefore offer you the best possible support in the continuation and execution of your projects.

For the entire former Brunner Thermo employees we wish all the best in these challenging times.

16. November 2020

COVID-19, postponed orders and projects all around the world: REVIEWing THE FIRST HALF of 2020

Within the last 6 months, Anytherm engineered and processed projects all around the world: from England to South Africa; from France to Vietnam.

Looking back at the first half year 2020, Anytherm resumes challenging as well as successful times. Caused by the COVID-19 pandemic, several potential Anytherm projects had been postponed. In order to be on track when returning towards the “business as usual”, Anytherm engineered and processed projects on its own risk before getting the official order. Thanks to our loyal and trustworthy customers, this has paid off as delayed orders have finally been received, allowing us to have our workforce available for additional new projects.

27. August 2020

At your disposal with full working capacity

In these challenging times we are pleased to inform that we are able beeing at your disposal with full working capacity - while respecting and complying with the current safety regulations.

Anytherms modern IT infrastructure offers the possibility for web and video conferences via MS Skype or Teams (or any other common web conference tool) having the possibility to share screens to efficiently discuss your project requests.

Our production capacities are available and we can manufacture your devices within the usual delivery times.

We consider it a matter of course to inform you transparently in case of changed conditions affecting your project inquiries and/or running projects.

Recovering Oil from Contaminated Exhaust Air Of the printing industry

For an application within the printing industry, Anytherm realized a heat exchanger unit to recover oil from polluted exhaust air. During the drying of printing inks, water, mineral oil and CO2 is released through evaporation into polluted exhaust air. Our heat exchanger unit cools down the contaminated exhaust air, so that the contained substances condense and can then be recycled. The recovered oil can be refined and finally sold and used again. Resulting in clean air at the end of the process, this can eliminate the need of the energy and CO2-intense thermal post-combustion of the polluted exhaust air.

The successfully completed project, which included installation and isolation at the customers site, proves our ability in designing customized systems for various special applications - always aiming for the optimal solution in terms of technology, economy and ecology.

Merry Christmas And happy new Year

An eventful year is ending and we look back to many exciting projects. We would like to take this opportunity to thank you for your trust and the successful and pleasant cooperation throughout the year. We wish you a Merry Christmas and a successful and happy New Year.

24. December 2019

Electrical Heating Unit Delivered to Finland

Anytherm recently delivered an Electrical Air Heater with a capacity of 70'000 kg/h as well as a Cooling Dehumidifier Unit with a flow rate 80'000 kg/h to a customer in Finland. With our Electrical Heating solutions, process air can be heated up to 400°C using electricity as energy source. Electrical heating elements can be integrated in all of our customized products - e.g. as extractable part installed in an insulated casing.

Further information about our Electrical Heater solutions can be found in the Products section of our website.

Deliveries to Singapore, Germany and Denmark

For a customer in Singapore, we recently delivered a Sorption Wheel Unit and a Fines Return Filter Unit. The Sorption Wheel Unit consists of a cooling pre-dehumidifier drying air from 25 to 11 g/kg which is then further dehumidified by means of absorption to 2 g/kg. A Pre Heater Recuperator was recently delivered to a customer in Denmark and is used for energy recovery of process air. For a German customer in the food industry an Exhaust-Air-Recuperator was delivered. The unit processes 140'000 m3/h of exhaust air and provides 740 kW of heat recovery.

We would like to thank our customers for the appreciated cooperations and look forward to continuous collaborations and projects.

New Reference List Available

More than 2 million kilograms per hour of production and exhaust air which is processed and/or recovered by our heat exchange and heat recovery units delivered within the past two years! We would like to express our gratitude to our customers all over the world for the trust placed in us.

Don't hesitate contacting us if you want to receive our reference list to learn more about our numerous and versatile projects.

Two Sorption dehumidifier Units for spain

Two identical Sorption Dehumidifier Units have been manufactured and timely delivered to Spain where they are currently being installed in a food processing plant. The two units consist of sorption dehumidification wheels, electrical heaters and filter stages and are completely made from stainless steel. The casing is insulated to reduce energy losses into its surroundings. The wheels, electrical heaters and filters are easily accessible via the insulated doors.

Don't Miss Any News From Us by Following Us on LinkedIn