Dessicant Wheel Dehumidifiers / Sorption Dehumidifier Units / Adsorption Dehumidification

Efficient and Customized: Industrial Desiccant Dehumidifiers

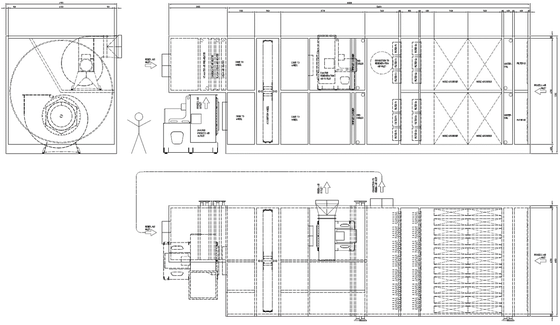

Regeneration Air Outlet:

- The regeneration air in couterflow dries out and therefore «regenerates» the sorption wheel

Process Air Inlet:

- Up to 200’000 kg/h

- Usually flows through 180° up to 270° sector (as shown) of the sorption wheel

Regeneration Air Inlet:

- Temperatures in the range 120-170°C

- Usually flows through 90° (as shown) up to 180° sector of the sorption wheel

Process Air Outlet:

- Can be dried down to below 2 g/kg humidity without condensation

Main Features

- Unit to dehumidify process air without condensation

- Making use of the adsorption process defined as the accumulation of molecules on a surface

- Core part is the so called sorption (or dessicant) wheel which accumulates (adsorbs) the water dissolved in the process air on its surface

- Many additional components can be included in the sorption units (see optional equipment) according to the client specification and request

Selected Project References

Click on the images to enlarge.

Materials And Characteristic Values

- Sorption wheel (also known as desiccant wheel): silica gel

- Rotation: maintenance-friendly chain drive with a constant speed of around 10 to 15 rotations per hour

- Seals: radial and axial seals (as shown on the right) to separate the two counter flows from each other and from the surroundings

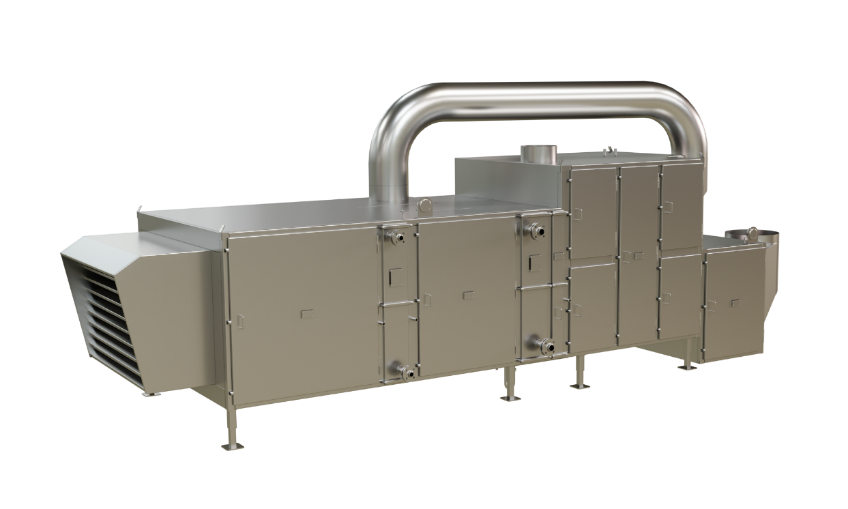

- Housing: Stainless steel with mineral wool insulation

Optional equipment

- Regeneration air heater (e.g. steam)

- Pre-cooler (condensation dehumidifier) for higher drying capacity

- Air cooler after the sorption wheel (as the air gets heated up by the drying process)

- Heat recovery systems

- Sound attenuators

- Filter stages for both process and/or regeneration air

- And more...

Customized according to client specification and request

Tailored Solutions for Diverse Industrial Applications

Anytherm stands as a leader in industrial dehumidification technology, delivering advanced Desiccant Wheel Dehumidifiers tailored precisely to the unique demands of the process industry. Our commitment to customization, utilization of top-tier materials, practical design, competitive pricing, and applications across dairy processing, food processing, pharmaceuticals, chemicals, and battery production ensure consistent delivery of reliable solutions across a diverse spectrum of international industrial settings. Our advanced Desiccant Wheel Dehumidifiers, also known as Sorption Dehumidifier Units or Adsorption Dehumidification systems, are crafted for efficient and customized industrial dehumidification, finding application across various industries.

Desiccant Wheel Dehumidifiers designed to excel in demanding industries

- Dairy Processing

- Food Processing

- Pharmaceutical Applications

- Chemical Applications

- Battery Production

In these sectors, where precise humidity control is paramount, our units play a crucial role in maintaining optimal conditions for production processes.

Exceptional performance in managing diverse operating parameters

Our Desiccant Wheel Dehumidifiers are engineered to excel across a spectrum of operating parameters, ensuring optimal performance in various industrial settings. Capable of handling process air inlets of up to 200,000 kg/h, the air typically flows through a sector of the sorption wheel ranging from 180° to 270°. Meanwhile, the regeneration air inlet operates at temperatures ranging from 120-170°C, traversing a sector of the sorption wheel from 90° up to 180°. The counterflow of regeneration air efficiently dries and regenerates the sorption wheel. Finally, the process air outlet achieves humidity levels below 2 g/kg without condensation, making it a reliable choice for industries with stringent humidity control requirements.

Efficient and Controlled Dehumidification process

At the core of our Desiccant Wheel Dehumidifiers lies the adsorption wheel, using silica gel for optimal adsorption capabilities. The rotation mechanism, maintained by a maintenance-friendly chain drive, operates at a constant speed of around 10 to 15 rotations per hour. The seals, both radial and axial, separate counter flows and surroundings, ensuring efficient and controlled dehumidification processes. The housing of our units is constructed with stainless steel, offering durability, and is insulated with mineral wool to enhance efficiency in challenging industrial environments.

Enhancing the versatility of our Desiccant Wheel Dehumidifiers

We offer a range of optional equipment tailored to specific industry needs. This includes regeneration air heaters (e.g., steam) to optimize the regeneration process, pre-coolers designed for increased drying capacity, air coolers positioned strategically after the sorption wheel to manage temperature variations induced by the drying process, heat recovery systems for energy efficiency, sound attenuators to minimize noise levels, and filter stages catering to both process and regeneration air. This flexibility in optional equipment ensures that our units can be finely tuned to meet the unique requirements of each client, providing a comprehensive and tailored industrial dehumidification solution.

Competitiveness in International Markets

Anytherm offers internationally competitive prices, ensuring our clients receive high-quality solutions without compromising affordability. This commitment, coupled with our dedication to customization, high-quality materials, and practical design, positions us as a reliable and cost-effective choice in the global marketplace.

Get impressions about our high quality products by viewing the photographs shown in the home section of our website.